Steel Transformations Caused by Welding

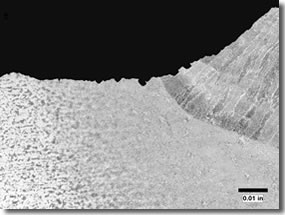

200x magnified vew of weld metal deposits

(upper left corner) joined to the parent

metal through a heat affected zone.

The parent metal has a typical structure

(bottom right).

Skeletons of all modern structures, I-beams or plate-steel, consist of low carbon steel, often joined by welding. All welding processes consist of localized melting of the steel (fusion) where two or more members of the structure must be joined.

The fusion weld is between similar metals. Thus, the welding rod is designed to mix with the base metal of two steel plates that must be joined. The welding rod and a layer of the base metal on either side of the two plates fuse and mix together. When the welding heat is removed, the fused mix, consisting of the welding rod and plate metal on either side of the molten rod, solidifies into a strong joint.

Next to the layer of base metal that has melted is a layer of steel that had been heated. The layer can extend as far as 1 inch into the base metal and although its composition has not changed, the heating causes subtle changes in its structure. In the case of low carbon steel, the heat affected zone (HAZ) could experience grain growth. If the carbon steel contains more than 0.2 percent carbon, the HAZ may also show effects of transformation of austenite.

Most modern steels are compounded with small additions of elements that are designed to improve their properties. These elements increase the equivalent concentration of the carbon. If for example, the low carbon steel (about 0.12 percent carbon) also contains manganese, copper, chromium etc., its carbon equivalency (CE) is determined by:

CE = %C + Mn/6 + Ni/15 + Cu/15 + Cr/5 + Mo/5 + V/5

(Metals Handbook, Desk Edition, 2nd Edition. Metals Park, Ohio: ASM International, 1998.)

Bridge collapses are not all that recent

If the steel base metal contains 0.12 percent carbon, 2-percent copper, 1 percent manganese, 1 percent nickel, ½ percent each of chromium and molybdenum, the calculated CE will be 0.67 percent. This carbon steel, although classified as low carbon, on welding will in the HAZ behave as if it were high carbon steel, very sensitive to thermal transformation in the heat affected zone that can result in cracking. For this reason, care must be taken to preheat and post heat the HAZ.