The Solution to Protection of Water Tanks from Corrosion

Ageing water tanks present a corrosion problem to municipalities that are expensive to remedy. The obvious solution would be to replace the aged water tank, but that could cost several million dollars for new real estate, site preparation, and at times environmental impact studies. The attendant problem would be time delays, sometimes lasting for years, while the old tank keeps leaking.

Another solution would be to recoat the insides of the tank with corrosion resistant paint. This is an effective solution, but there are drawbacks. It is expensive and not an immediate fix because the tank must be taken out of commission for lengthy periods. Recoating is a multi-step process. The tank must be drained, dried and inside surfaces must be cleaned, often by sand blasting. Primer coating must follow the sand blast almost immediately. Only then can a final coat be applied to let dry. The entire process can take 3 months and meanwhile, delivery of water to municipal customers is disrupted.

In contrast to this expensive and inconvenient scenario, the national standards organizations AWWA/ANSI and NACE have standards D106-2010 and RP0388-2001, respectively, that advocate cathodic protection. Corrosion Services installs cathodic protection following the guidelines of both of these recognized standards.

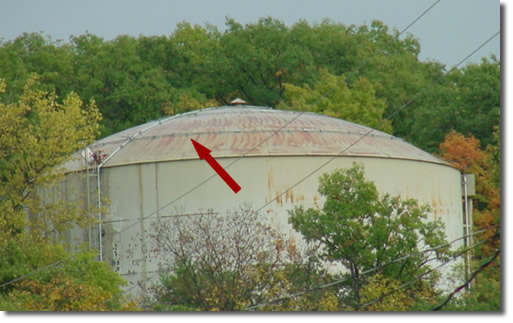

This tank was erected in 1965. It

has been cathodically protected without

an inside coating since 2007. There are 25 anodes inside the tank. On

the roof

can be seen the conduits (arrow) that run the anode cables to a

rectifier.

Cathodic protection can be applied without disruptions to a municipality's water supply. Holes in the water tank roof for anodes are cut while the tank is full of water in continuing service. Once cut, anodes, first sterilized with 5% ChloroxTM, can be inserted. Each anode is designed to protect a section of the tank's content and has a projected life of over 20 years. Once inserted, the anodes are connected to the positive pole of a rectifier. The negative pole of the rectifier is then connected outside on the chime of the tank. (A chime is the ground ring to which are welded the vertical walls of the tank.) The rectifier is turned on and the tank is protected.

The hole into which an anode will be

inserted.

The anode itself looks like an insulated electrical cable,

typically, AWG #8 with HMWPE insulation. It can be 20 feet

in length. It is connected to an insulated electrical cable

that runs through the conduit to the positive pole of the rectifier.

Capital costs associated with cathodic protection run approximately $0.04 per gallon of tank capacity. For each million gallon capacity, this translates to $40,000. Costs associated with its operation are limited to electricity. It takes less than 60 watts to protect a tank with a capacity of 1 million gallons, about $50 annually.

Air cooled rectifier for the water

tank.